Introduction

Due to the randomness of possible serious errors, the process measurements performed by chemical plants or refineries often do not meet the limits of material and energy balance.

The randomness of the possible errors can be adjusted using data reconciliation in a weighted least-squares sense to comply with process limitations.

This topic will identify sources of errors in blending operations, analyzer dynamics, online analysis versus lab analysis, causes and remedy of online analysis errors, use of last good value and bias, flow correction methods, tank prediction bias, and final product prediction vs. lab analysis.

Errors and Correction Techniques in Blending Technology

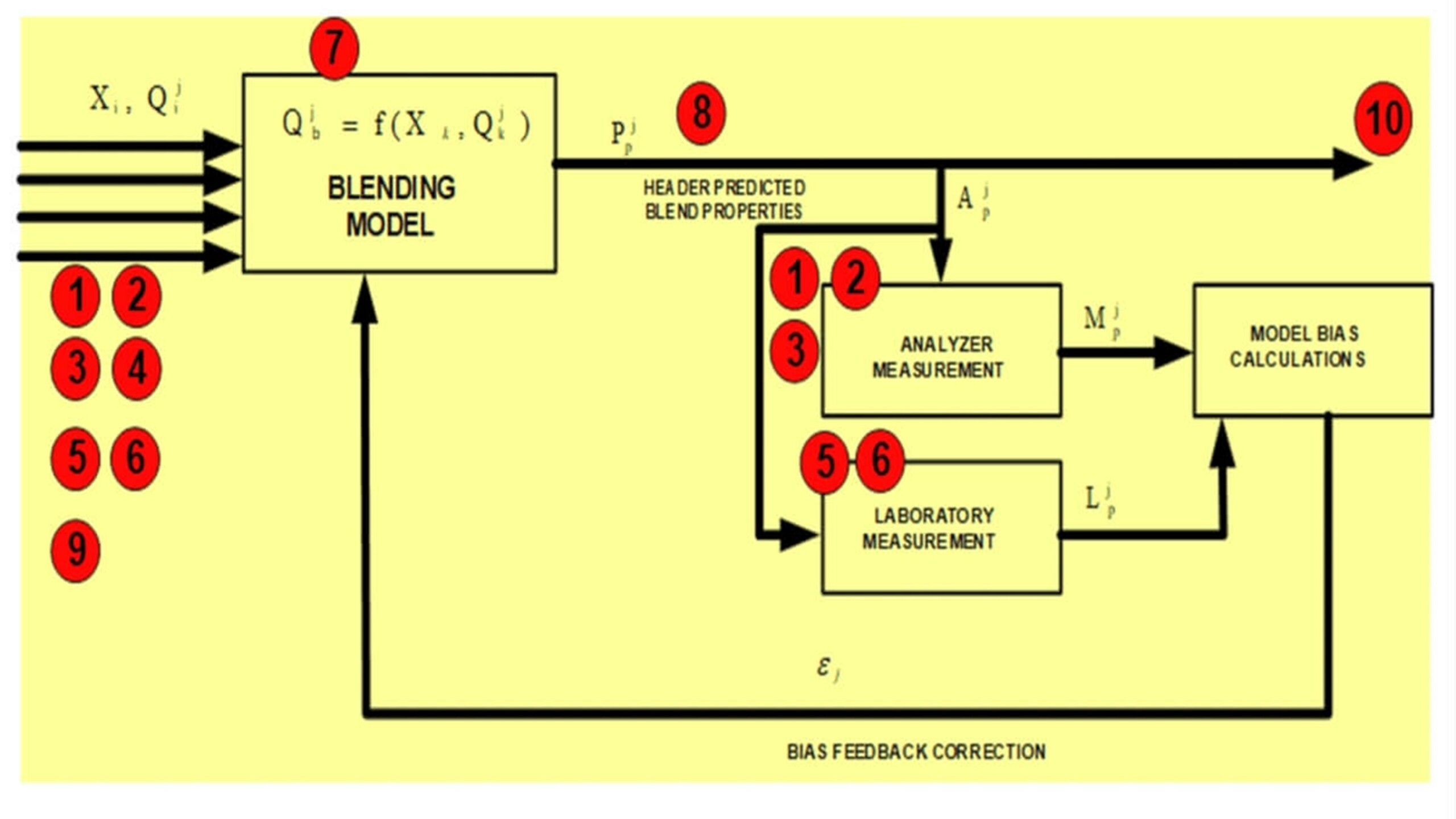

In refineries, sources of possible errors during blend operations may include flow measurement errors, transport and dead time lag in the analyzer measurement, lag in dynamic analysis (it measures the dynamic response).

Also, human error factors during a lab analysis measure qualities by online analyzers for component streams and blend header, and inaccuracies in blending methods and qualities correlation.

Biased correction is done for these blend errors based on blend product and recipe. It is not constant, but its implementation is easy, and it works under diverse conditions. Additional corrections are done for unknown non-linearity and interaction by combining this method with other methods in blending models.

An overall biased correction for the blended model is composed of lab analysis bias, analyzer bias, blend model bias, and final tank bias. Statistically averaged bias is used or preferred for these stated biases.

The flow correction method is used to accomplish correction inflows because flow measurement of blending streams is equally as important as qualities.

The corrected flow is the sum of raw flow, zero offsets (raw flow at zero output), and calibration correction. Refineries learn and use the whole reconciliation process to optimize/customize the parameters used in the models as per their refinery’s processes.

They do this by using historical data regression. Dupont’s coefficients, ethyl equation constants, indexed constants, and NIR models’ parameters are customizable blend parameters. They learn the mixture’s volatility and standardize the measurement of volatility using RVP. If the temperature is anything but 1000 F, then there is a difference between true vapor pressure and RVP concerning the mixture.

Summary

The blend models are customized by a biased correction to avoid compromised blend quality due to errors in blending operations. The customization of blend models by regression of historical blend data is recommended. It is simple to use and integrated with blend control and optimization systems to avoid poor qualities.

Options for eLearning This Topic

Click to enroll for the eLearning of this topic on the data reconciliation and feedback

Browse Our Academy Course Catalog

#OnlineBlendingAnalyzers #BlendProductRecipe #RefineryZeroOffsets #RefineryBlendHeader #BlendingStreamsMeasurement #Dupont’SCoefficientsParameters #NirModels #EthylEquationConstantsModel #CustomizedBlendModels #IndexedConstantsModel

1 2 3 4 5 100%

1 2 3 4 5 0%

1 2 3 4 5 0%

1 2 3 4 5 0%

1 2 3 4 5 0%